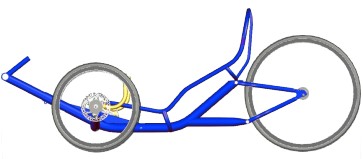

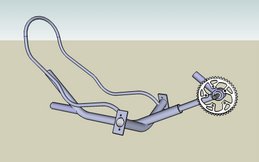

Here is the donor bike I bought for the Road Rooster project. I got it for $20 at the police auction in Winnipeg (but with no seat). I need the rear wheel, crank assembly, both brakes, derailers and grip shifters as well as cutting off the rear triangle. I like the tires it has too!

Here is the donor bike I bought for the Road Rooster project. I got it for $20 at the police auction in Winnipeg (but with no seat). I need the rear wheel, crank assembly, both brakes, derailers and grip shifters as well as cutting off the rear triangle. I like the tires it has too!But here is a problem. I took it for a couple rides and I think I like it better than my good 2 wheel bike... but I am not about to cut up my good bike for the Road Rooster... decisions, desisions...

Total cost: $20.00

Total project parts cost to date: $131.10

Total project cost to date: $138.29

Project budget: $200

Remaining budget: $61.71