Ok, today we finish the welding jig we started yesterday, we left off with the cross tube part of the jig finished:

Cut a hole for the main tube to fit through. Obviously not a precise hole.

.

Now screw 2 pieces of melamine together to square the piece the main tube will be attached to.

Butt the cross tub jig up.

Position the cross tube so it is centered on the main tube. Since the cross tube is now level, you just have to make sure the main tube sits down evenly in its notch. hmmm that reminds me I am not sure I checked that the notch is square to the main tubes bend, will have to check before welding...

Screw the cross tube jig to the piece the main tube is attached to.

We can now remove the piece used to as a square

Now we screw a square piece in the corner to square it that way (such precise words)

Now we fine tune where the main tube is sitting, this part should be level

Whoops! The table isn't level! The jig has to be moved to the garage for welding, so I will re-level everything there.

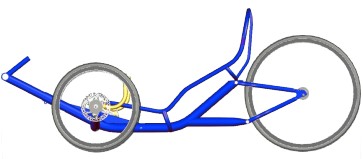

The jig is done! I feel like I should be doing a whole bunch of measuring to check everything, but that was the whole problem in the first place, no places to precisly measure from...

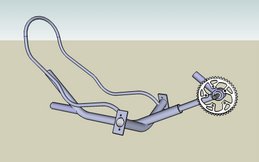

Today I tack welded the piece that extends from the back of the main tube. Took a little bit of re-doing to get it straight but I was rewarded because it is bang on now. This piece will be trimmed to length once I establish how high the rear wheel needs to be, and thus how the rear triangle lines up. This was a most satisfying task.

Today I tack welded the piece that extends from the back of the main tube. Took a little bit of re-doing to get it straight but I was rewarded because it is bang on now. This piece will be trimmed to length once I establish how high the rear wheel needs to be, and thus how the rear triangle lines up. This was a most satisfying task.