I received my router bit I bought on eBay today. "What does that have to do with trike building?" you may ask. To fabricate the seat frame I have to do some somewhat complex bending of 1" aluminum tubing

(LINK). I could buy a conduit bender but as Grant points out, I am too cheap ;) A bender (

LINK) costs at least $33.00 and I would probably need 2 of them. I can make my own bender like this

LINK or an alternate method is to build a bending jig out of wood. Here is a

LINK to an example. I am probably going to build a jig but add the curved trough that the bender has to lower the possiblity of kinking the tubing. THAT is where the router bit comes in. I will assemble the jig, then cut a groove for the tube to sit in as it is being bent. Clear as mud??? I will post some pics when I start bending some tube.

Cost = $2.10 for the bit, $5.09 for shipping from the UK for a total of $7.19 CAD ($45 at Lee Valley). Total project cost to date $37.32

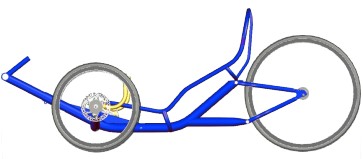

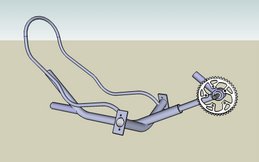

This is the assembled seat frame. It is comprised of 3 pieces of 1" aluminum, the 2 sides and the top hoop.

This is the assembled seat frame. It is comprised of 3 pieces of 1" aluminum, the 2 sides and the top hoop.